Quality Assurance

Tongyu Heavy Industry Co., Ltd. has successfully finalized the delivery of essential supporting products for the pumped storage power station, which boasts the largest single-unit capacity in China

Release time:

2024-10-28

Author:

Source:

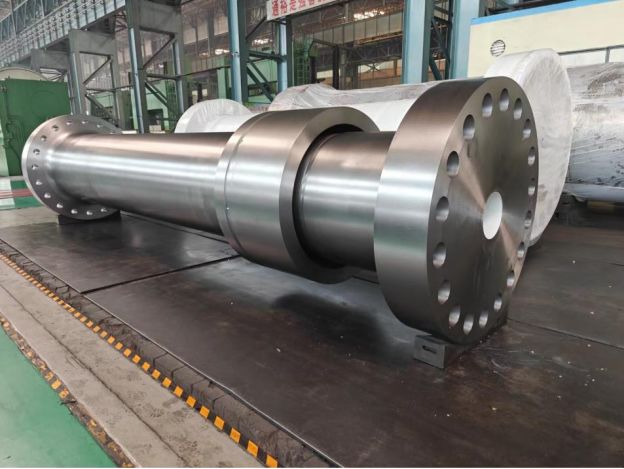

Tongyu Heavy Industry Co., Ltd. has recently accomplished the successful delivery of the final hydro turbine shaft to Harbin Electric Machinery Company Limited for the Tiantai Pumped Storage Power Station Project, which is being developed by China Three Gorges Construction Engineering Group. This power station is notable for being the largest pumped storage facility in China in terms of single-unit capacity. To date, it has supplied a total of four hydro turbine shafts, four generator shafts, and several yoke ring forgings for this project, thereby fulfilling all delivery obligations associated with the project's products.

(Generator shaft)

(Generator shaft)

The Tiantai Pumped Storage Power Station Project represents a significant initiative within the framework of China's "14th Five-Year Plan" and is a pivotal component of the "Medium and Long-Term Development Plan for Pumped Storage (2021-2035)." This power station boasts a rated water head of 724 meters, making it the highest of its kind globally. With a single-unit capacity of 425,000 kilowatts, it holds the distinction of being the largest pumped storage power station in China, thereby imposing stringent requirements on unit design, equipment manufacturing, and construction and installation processes. The generator shafts and hydro turbine shafts produced by our company are essential core components of the pumped storage units, playing a vital role in ensuring the stable operation of the power station. To facilitate the timely delivery of project products,our corporation leveraged its extensive technological and equipment expertise developed over many years in large-scale equipment manufacturing. An experienced research and development team, along with key production personnel, was assembled to execute meticulous design and precise processing, ensuring that each phase of production was completed to the highest quality standards. Ultimately, all products were delivered in accordance with the established schedule.

Following years of dedicated cultivation, our company has established a comprehensive industrial chain encompassing research and development, as well as the production of large castings, forgings, and structural components. Its product offerings span a wide array of sectors, including wind power, hydropower, maritime vessels, and marine engineering equipment. Leveraging its robust production and manufacturing capabilities, alongside rigorous quality control measures, our firm has successfully supplied products for numerous national key projects. Looking ahead, the corporation remains steadfast in its commitment to the development vision of "dedicating itself to creating a sustainable future for humanity," with the objective of "becoming a world-class supplier of high-end equipment and new energy solutions." It will persist in enhancing its technical expertise and manufacturing capabilities, thereby contributing to the high-quality advancement of China's equipment manufacturing sector and the successful realization of the national "dual carbon" strategic objectives.

Key words:

SUBORDINATE SUBSIDIARIES