Facility Series

MELTING

The company owns 2 sets of advanced 50t and 100t UHP electric arc furnaces, 20, 50t, 150t LF furnaces, 20t, 50t, 150t VD/VOD furnaces, and 10 sets of vacuum casting equipment which can product largest ingot up to 450 tons. lt also has 11 setsof water-cooled ingot mold for producing water cooled steel ingot up to 75tons, and 6 sets of 20t, 30t, 40t electro-slag remelting furnace which can supply largest ESR ingot up to 100 tons.

ESR

The company owns six sets of ESR Furnaces including 20t,30t,40t single-phase furnaces and three-phase ESR furnaces,In them, the 30t ESR furnace is three-phase double arms single smelting position extracting single type CNC ESR furnace, this equipment is in the domestic leading level. We have excellent melting team, rich melting experience and sophisticated equipments, the qualities of our products are definitely reliable. We can manufacture ESR ingots ranging in weight from 3 ton/pc to 80 ton/pc, and there are various kinds of materials including low-carbon high alloy steel, vessel steel, cold roller steel, rotor steel, steel used in nuclear power station, stainless steel and etc. In the May of 2010, we successfully melted the large ESR ingot used for AP1000 nuclear power main piping.

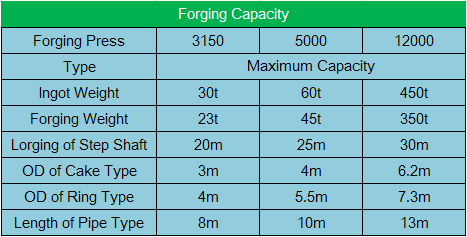

FORGINGS

The company owns 120MN,50MN,31.5MN and 12.5MN Forging Press and matched with manipulators,forging cranes and 22 sets of heating furnaces wihch forms the systematic forging production capacity fo 200,000 tons,and largest forging weight as 350 tons.

HEAT TREATMENT

The company has more than 40 sets of various car-bottom type heat treatment furnaces wiht max length as 25m and width as 7m,and 16 sets of vertical furnaces with max depth of 30m,1 set of cover-type furnace with dimension 3x20m,as well as 25MN and 30MN self-developed hydraulic straightening machine.The annual outpput of heat-treatment capacity is 150,000 tons.

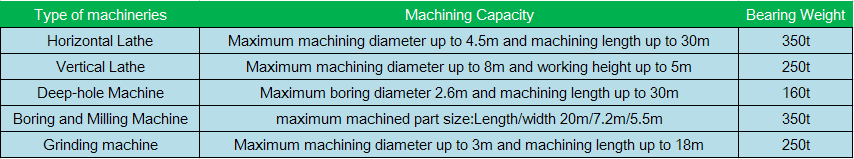

MACHINING

The company owns more than 320 sets of various heavy-duty machineries, including NC gantry boring and milling machining center, MC floor type boring and milling center, NC horizontal lathe, NC vertical lathe, NC roll grinding machine and deep-hole drilling and boring machine which can complete all kinds of machining process like turning, boring, drilling, grinding and milling.

CASTING

The company has advanced resin sand production line and 9 sets of 60t, 30t, 20t, 10t medium frequency induction furnace which can product all kinda of gray iron casting, ductile iron casting, alloy iron casting, anti-wear and anti-corrosion iron casting, heat-resisting iron casting;and the largest iron casting is up to 200 tons, annual capacity as 100, 000 Tons.

WELDING

The company has twin-wire narrow-gap submerged arc welder, tube sheet automatic welder, inner bore welder, MC flame cutting machine, plasma cutting machine, steel plate shearer, pipe-bending machine, bending machine and other advanced welding equipment. There are more than 40qualified welding engineers with international welding certification and pressure vessel welding certifications.

SUBORDINATE SUBSIDIARIES