The independently developed "DN3000 pipe mold" and "all fiber integrated forming magnetic yoke ring forging" by Tongyu Heavy Industry have passed the scientific and technological achievement appraisal

Release time:

2023-07-13

Author:

Source:

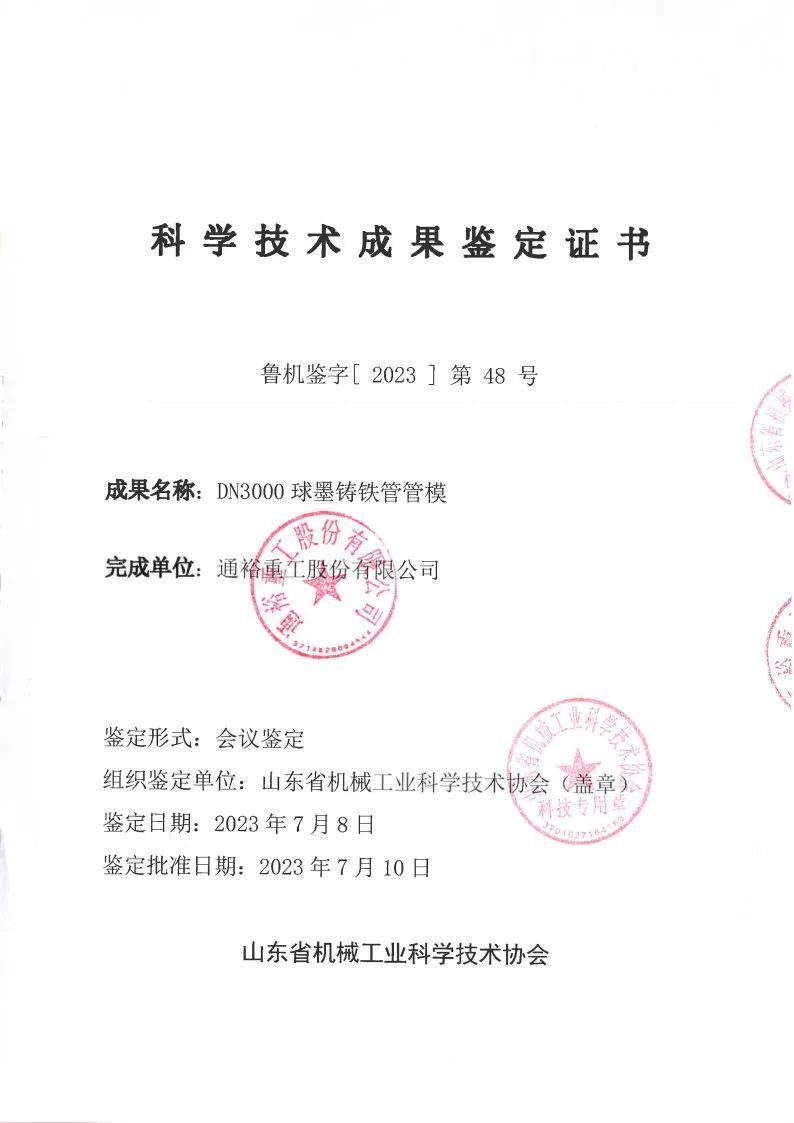

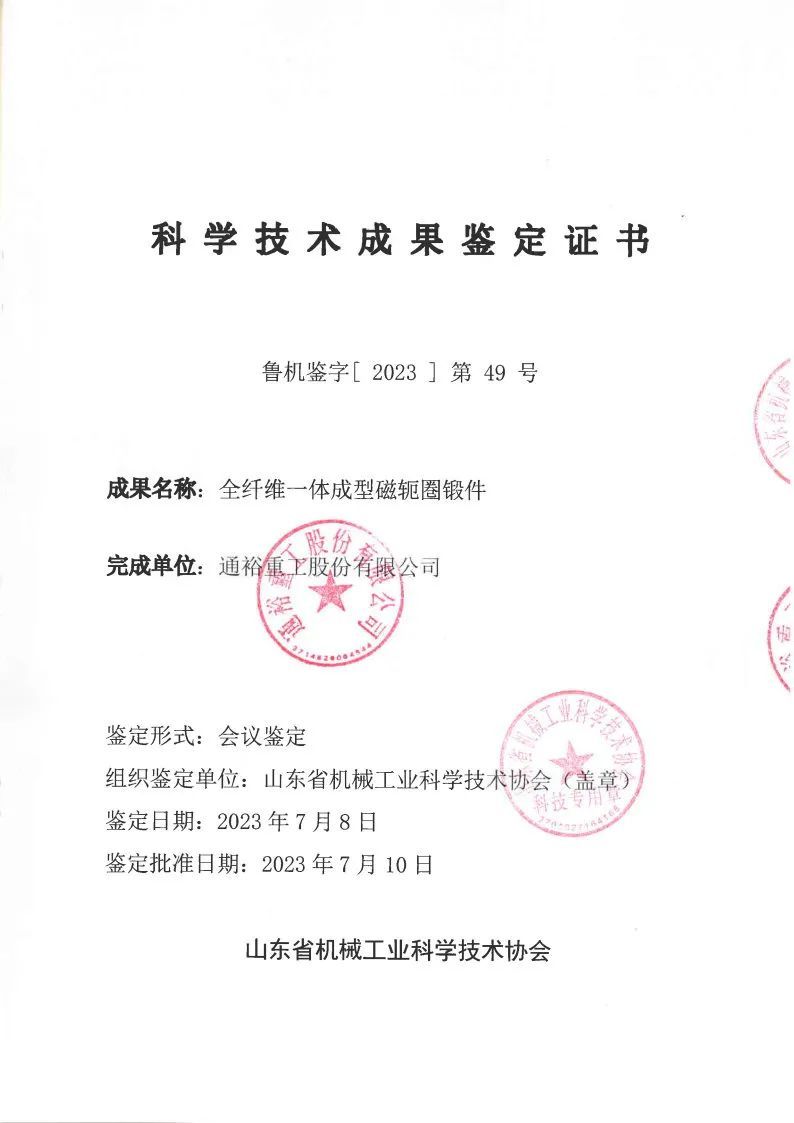

Recently, Tongyu Heavy Industry Co., Ltd. commissioned the Shandong Machinery Industry Science and Technology Association to organize industry experts to hold a scientific and technological achievement appraisal meeting for "DN3000 pipe mold" and "all fiber integrated forming magnetic yoke ring forgings" in the form of online meetings. The appraisal committee is composed of seven experts, including Zheng Zhongcai, a professor of Shandong Construction University, Guan Yanjin, a professor of Shandong University, Wang Yangming, a professor of University of Jinan, Wang Hongyan, an expert of Shandong Machinery Industry Expert Committee, Jing Shiji, a professor of Shandong Construction University, Chen Ruchang, a researcher of Sinomach Casting and Forging Co., Ltd., and Yin Liang, a senior engineer of Shandong Machinery Design and Research Institute. After careful discussion among the attendees, the appraisal committee unanimously agreed that the overall technology of both products has reached the international advanced level.

DN3000 pipe mold, with a length of 6.78 meters, an outer diameter of 3.4 meters, an inner diameter of 3.13 meters, and a total forging weight of 153.7 tons, is currently the world's largest ductile iron pipe mold. The company has developed a large ductile iron pipe mold forging process, a new process for smelting and pouring large steel ingots, and a heat treatment process for large pipe mold with strong water cooling and water cooling movement, ensuring all technical indicators of the product and meeting design requirements. The successful development of this product has further expanded the coverage of the company's large pipe mold products, enhanced the global influence and market share of the company's pipe mold products, promoted the optimization and technological upgrading of China's water conservancy system, and promoted national energy security and sustainable development.

The company has developed an integrated near net forming technology for large magnetic yoke rings used in pumped storage, using full fiber streamline control, rotary forging, and membrane forging processes to achieve the integrated forging of the magnetic guide block and yoke ring, omitting the welding process, saving materials and energy, and improving production efficiency and product service life. The successful research and development of the full fiber integrated forming magnetic yoke ring forging product has further expanded the company's product range, which will assist in the optimization and technological upgrading of China's pumped storage industry structure.

The successful research and development of two products fully reflects the company's comprehensive manufacturing strength and technological equipment advantages in the entire industrial chain of steel ingot smelting, forging, heat treatment, and machining, which will further enhance the company's market competitiveness.

Key words:

SUBORDINATE SUBSIDIARIES